The costs associated with solar power have been falling steadily for decades, as improvements in manufacturing technology and economies of scale have wrestled within an increasingly competitive environment to realize consistent reductions in cost throughout the supply chain.

The lower price of solar plant components naturally translates to a lower price for the electricity they generate, and so solar energy has become increasingly competitive across a wider part of the globe.

According to IRENA, the

Lowering costs throughout the manufacturing process, especially notable with cells and modules, has been a major focus of suppliers, and has helped spur the explosion of applications of solar in the past two decades.

Manufacturers continue to focus on reducing costs, but as improvements continue, the opportunities to achieve price reductions are getting harder to achieve.

The benefits of economies of scale generally continue to favor the largest manufacturers, while the cost of key inputs like electricity and labor costs will give an advantage to those in developing economies, as they have in China, especially. Also important, though, are the capital costs associated with the manufacturing process, which offer a unique opportunity to produce solar products at a lower cost.

The PUREVAP™ UMG process could make a significant dent in the cost of material inputs, in part through lower operating expenses (OPEX) in the production of Solar-grade Silicon (SoG-Si).

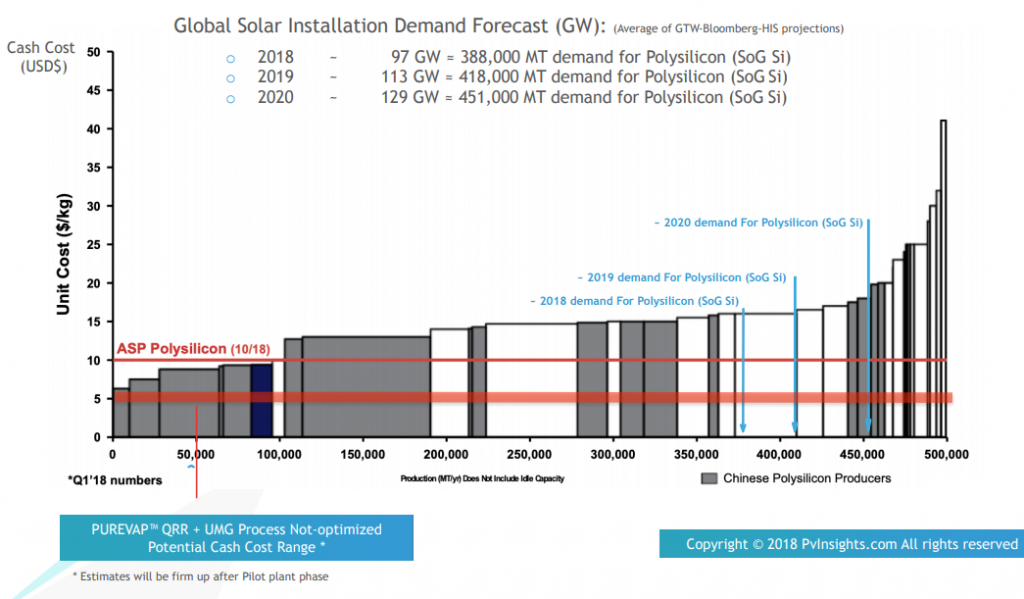

As demand for SoG-Si goes up, production costs tend to increase, as less efficient producers are able to realize the higher costs they need. Demand for SoG Si in 2018 was around 388,000 MT, and projections from major industry analysts show it growing to 418,000 MT in 2019, and 430,000 MT in 2020, in line with the continued expansion in solar PV along with other applications.

Globally, average unit costs at the 2018 demand level are in the range of $15 per kg, but with the current state of production that would be pushed up to near $20 per kg in order to meet the anticipated demand in 2020.

Successful bench tests conducted by HPQ and its partners have shown the HPQ PUREVAP™ Process can provide SoG-Si at a unit operating cost in the range of $5-6 per kg, far below the costs for virtually every major supplier in the industry.

This will give a considerable market advantage to HPQ and its partners, including Apollon Solar, a globally renowned manufacturer of high-performance multi-crystalline and monocrystalline solar cells.

The key to the lower OPEX is the patented PUREVAP™ process, based on the plasma technology developed by our partners at PyroGenesis, a world leader in advanced plasma processes.

Pyrogenesis has made it possible to transform Quartz (SiO2) into High Purity Silicon Metal (4N+ Si < 1 ppm B) in a single step, to produce “PUREVAP™ Si”. This is further refined through metallurgical processes to achieve solar grade silicon.

For us, the overall reduced OPEX makes the PUREVAP™ process a compelling and disruptive advancement in the manufacture of high purity silicon for the solar sector.

HPQ Silicon is a Quebec-based TSX Venture Exchange Tier 1 Industrial Issuer. With the support of world-class technology partners PyroGenesis Canada and NOVACIUM SAS, the company is developing new green processes crucial to make the critical materials needed to reach net zero emissions.